| 状态: | |

|---|---|

IP68

概述

Overview

该产品严格按照产品执行标准《GBT18940-2003封闭管道中气体流量的测量涡轮流量计》,《GBT21391-2008用气体涡轮流量计测量天然气流量》和检定标 准《JG1037-2008涡轮流量计检定规程》来执行和检定。

The product is implemented and verified in strict accordance with GBT18940-2003 Measurement of Gas Flow in Closed Conduits - Turbine Meters, GBT21391-2008 Measurement of Natural Gas Flow by Turbine Meters and JG1037-2008 Verification Regulation of Turbine Flowmeter.

该产品经国家防爆产品质检部门按GB3836.2000 《爆炸性气体环境用电气设备第1部;通用要求》,GB3836.2-2000《爆炸性气体环境用电气设备第2部分;隔爆型“d”》和GB3836.4-2000《爆炸性气体环境用电气设备第4部分:本质安全型T"》标准检验合格,防爆标志为Exd IICT6Gb/Exd IIBT6Gb (隔爆型)、 Exia IICT6Ga (本安型)。适用于含有IIA、IIB、IIC 类T1~T6温度组别爆炸性气体混合物的0(仅本安型)1、2区危险场所。

This product has passed the inspection by the national explosion-proof product quality inspection department according to GB3836.2000 Electrical Apparatus for Explosive Gas Atmospheres - Part 1: General Requirements, GB3836.2-2000 Electrical Apparatus for Explosive Gas Atmospheres - Part 2: Flameproof "d" and GB3836.4-2000 Explosive Atmospheres - Part 4: Equipment Protection by Intrinsic Safety "i". Its explosion-proof marks are Exd IICT6Gb/Exd IIBT6Gb (flameproof type) and Exia IICT6Ga (intrinsic safety type). It is applicable to hazardous areas in Zones 0 (intrinsic safety type only) and 1 and 2 containing explosive gas mixtures of temperature rating T1~T6 of Classes IIA, IIB and IIC.

产品特点

Product Features

1. 高精确度,一般可达±1.5%、±1.0%、±0.5%;

1. High accuracy, generally up to ±1.5%, ±1.0% and ±0.5%;

2. 采用新型叶轮组,始动流量低、压力损失小、抗振与抗脉动流性能好,不易腐蚀、可靠性好、使用寿命长。

2. The new impeller assembly features low starting flow, small pressure loss, good anti-vibration and anti-pulsating flow performance, corrosion resistance, high reliability, and long service life.

3. 设计有整流性能优良的整流器,前后直管段刚性需求降低。

3. The rectifier with excellent performance allows for reduced rigidity requirements of the front and rear straight pipe sections.

4. 超高量程比,最高可达1:20或更高。

4. Ultra-high range ratio, up to 1:20 or higher.

5. 采用新型微处理器与高性能的集成芯片,运算精度高,整机功能强大,性能优越。

5. The new microprocessor and high-performance integrated chip ensure high operational precision, powerful machine functions, and superior performance.

6. 按流量频率信号,可将仪表系数最多分九段自动进行线性修正,可根据用户需要提高仪表的计算精度。

6. The instrument coefficient can be automatically corrected linearly by up to nine segments according to the flow frequency signal, ensuring improved computational accuracy of the instrument based on users' needs.

7. 流量计表头可双向360°旋转,安装使用简单方便。

7. The flowmeter with its head rotating 360° in both directions is simple and convenient to install and use.

8. 重复性好,短期重复性可达0.05%R~0.2%R,正是由于 具有良好的重复性,在贸易结算中是优先选用的流量计。

8. The good repeatability, up to 0.05%R~0.2%R in short term, makes it preferred in trade settlement.

9. 独立式机芯设计,互换性好、维护方便。

9. The independent movement design ensures good interchangeability and convenient maintenance.

10. 独特的机芯自润滑系统,使得该产品在使用时可不保养或少保养。

10. The unique movement self-lubricating system makes the product maintenance-free or low-maintenance in its use.

11. 采用低功耗设计,可用内电池供电,电池可连续使用2年以上(无背光);同时也可外接电源。专用液晶显示屏(带背光),读数直观方便,可同时显示标况瞬时流量、工况瞬时流量、标况累积流量以及测量介质的温度、压 力等参数。

11. With the low power consumption design, it can be powered by the built-in battery continuously for over 2 years (without backlight); it can also be connected to an external power supply. The special LCD (with backlight) with readings intuitive and convenient can simultaneously display parameters such as standard instantaneous flow, standard instantaneous flow, standard cumulative flow, and measured medium temperature and pressure.

12. 采用进口仪表专用精密轴承,耐磨性好,稳定程度 高;同时提高了仪表的下限灵敏度,降低了始动流量。

12. The special precision bearing designed for imported instruments features good wear resistance and high stability, improved lower limit sensitivity of the instrument, and reduced starting flow at the same time,

13. 具有实时数据存储功能,可防止仪表突然掉电时数据丢失,在停电状态下,内部数据可永久性保存。

13. The function of real-time data storage enables the internal data to be permanently saved in the event of a power outage to prevent data loss in case of sudden power down of the instrument.

14. 可靠的电磁兼容设计,抗干扰性能好,可靠性高,满足JJG1037-2008标准的电磁兼容实验要求。

14. With the reliable design of electromagnetic compatibility (EMC), it has good anti-interference performance and high reliability, meeting the EMC test requirements specified in JJG1037-2008.

流量计结构

Structure of Flowmeter

工作原理

Working Principle

当气流进入流量计时,首先经过独立机芯的前导结构并加速,在流体的作用下,由于涡轮叶片与流体流向成一定角度,此时涡轮产生转动力矩,在涡轮克服阻力矩和摩擦力矩后开始转动。当诸力矩达到平衡时,转速稳定,涡轮转动速度与流量成线性关系,通过旋转的发信盘上的磁体周期性地改变流量传感器磁阻,从而使流量传感器感应出与流体体积流量成正比的频率信号。该信号经前置放大器放大、整形后和压力、温度传感器检测到的压力、温度信号同时输给流量积算仪的微处理器进行运算,转化显示标准体积流量和标准体积累积总量。

When entering the flowmeter, the airflow first passes through the leading structure of the independent movement and accelerates. As there is a certain angle between the turbine blades and the flow direction of the fluid under the action of the fluid, the turbine generates a rotating torque at this time and starts to rotate after overcoming the resistance torque and friction torque. When the torques reach equilibrium and the rotating speed is stabilized, there is a linear relationship between turbine speed and flow. The magnet on the rotating signaling disk periodically changes the reluctance of the flow sensor so that the flow sensor senses a frequency signal proportional to the volume flow of the fluid. After being amplified and shaped by the preamplifier, the signal is simultaneously output, together with the pressure and temperature signals detected by the pressure and temperature sensors, to the microprocessor of the flow totalizer for calculation, which is converted into the standard volume flow and the standard total cumulative volume for display.

流量积算仪原理

Principle of Flow Totalizer

流量积算仪由温度和压力检测模拟通道、流量传感器通道以及微处理单元组成,并配有各种输出模块。流量计中的微处理器按照气态方程进行温压补偿,并自动进行压缩因子修正,气态方程如下:

The flow totalizer, consisting of temperature and pressure detection analog channels, flow sensor channel and microprocesser unit, is configured with a variety of output modules. The microprocessor in the flowmeter performs temperature and pressure compensation according to the ideal gas law and automatically corrects the compressibility factor. The ideal gas law is shown below:

CKAS-FLOW880气体涡轮流量计

CKAS-FLOW880Gas turbine flowmeter

CKAS-FLQW990气体涡轮流量计

CKAS-FLQW990Gas turbine flowmeter

技术参数

Technical parameters

流量范围表及耐压等级

Flow range table and voltage ratin

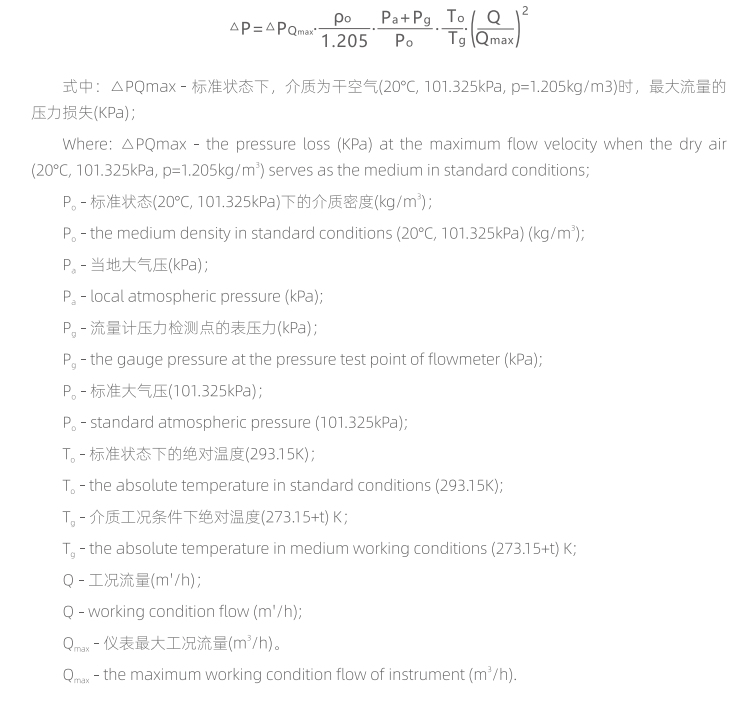

流量计的压力损失计算:

Calculation of Pressure loss of Flowmeter:

举例:

Example:

涡轮流量计的压力损失与涡轮的驱动、管道内部的摩擦以及流体的速度和方向有关,涡轮在工况条件下的压力损失可用下式求得:

The pressure loss of the turbine flowmeter is related to the drive of the turbine, the friction inside the pipeline, and the velocity and direction of the fluid. The pressure loss of the turbine in working conditions can be obtained by the formula below:

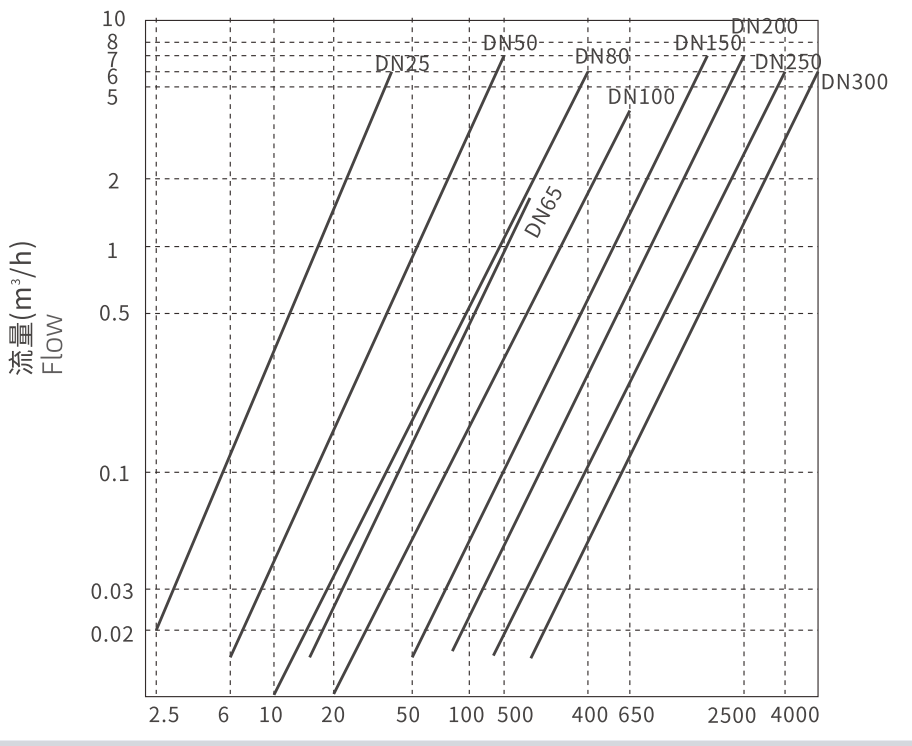

流量计压力损失曲线

Pressure Loss Curve of Flowmeter